Blowoff valve

A blowoff valve is a pressure release system present in turbocharged engines, its purpose is to prevent compressor surge and reduce wear on the engine.

Definitions

A compressor bypass valve (CBV) also known as a compressor relief valve is a vacuum-actuated valve designed to release pressure in the intake system of a turbocharged or centrifugally supercharged car when the throttle is lifted or closed. This air pressure is re-circulated back into the non-pressurized end of the intake (before the turbo) but after the mass airflow sensor.

A blowoff valve, (BOV, sometimes hooter valve, dump valve) does basically the same thing, but releases the air to the atmosphere. This creates a very distinctive sound desired by many who own turbocharged sports cars. Some blowoff valves are sold with trumpet shaped exits that amplify the "Psshhhh" sound, these designs are normally marketed towards the tuner crowd. For some owners this is the only reason to get a BOV. Motor sports governed by the FIA have made it illegal to vent unmuffled blowoff valves to the atmosphere. In the United States, Australia and Europe cars featuring unmuffled blowoff valves are illegal for street use.

Downsides of releasing air to atmosphere

The unique sound caused by a blowoff valve (but not a compressor bypass valve) sometimes comes at a price. On a car where the blowoff valve is mounted after the mass airflow sensor, venting to atmosphere confuses the engine control unit (ECU) of the car. The ECU is told it has a specific amount of air in the intake system, and injects fuel accordingly. The amount of air released by the blowoff valve is not taken into consideration and the engine runs rich for a period of time. Engines with a manifold absolute pressure regulated ECU or where the blowoff is mounted upstream of the MAF sensor are not affected.

Typically this isn't a major issue, but sometimes it can lead to hesitation or stalling of the engine when the throttle is closed. This situation worsens with higher boost pressures. Eventually this can foul spark plugs and destroy the catalytic converter (when running rich, not all the fuel is burned which can heat up on and melt the converter or leave heavy carbon deposits).

Purpose of Relief and Blow Off Valves

Blowoff valves are used to prevent compressor surge. Compressor surge is a phenomenon that occurs when lifting off the throttle of a turbocharged car (with a non-existent or faulty bypass valve). When the throttle plate on a turbocharged engine running boost closes, high pressure in the intake system has nowhere to go. It is forced to travel back to the turbocharger in the form of a pressure wave. This results in the wheel rapidly decreasing speed and stalling. The driver will notice a fluttering air sound.

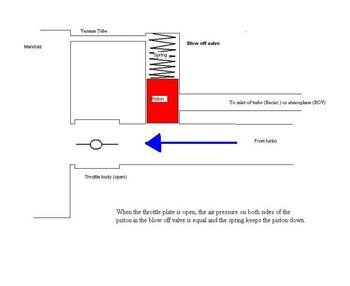

How it works

A blow-off-valve is connected by a vacuum hose to the intake manifold after the throttle plate. When the throttle is closed, underpressure develops in the intake manifold after the throttle plate and "sucks" the blowoff valve open. The excess pressure from the turbocharger is vented into the atmosphere or recirculated into the intake upstream of the compressor inlet.

Tuning adjustable valves

Most aftermarket valves are adjustable, leaving customers to set them properly for their specific vehicle. Typically the adjustment lies in the spring preload. One way to adjust it is as follows:

The spring should be set as soft as possible without leaking boost at peak pressure. If the spring is set too soft, the valve will not close fully, resulting in a boost leak and idle problems. If the spring is set too hard, the valve will not fully open, close too early, and cause compressor surge.

Trial and error with an accurate boost gauge is the perfect way to find the right setting for your vehicle...

References

Allard, Alan. Turbocharging and Supercharging. Cambridge, England: Patrick Stevens Limited, 1982.

Gorla, Rama, and Khan, Aijaz. Turbomachinery Design and Theory. New York, New York: Marcel Dekker, 2003.

Society of Automotive Engineers. Turbochargers and Turbocharged Engines. Warrendale, PA, 1979.

Watson, N, and Janota, N. Turbocharging the Internal Combustion Engine. London, England: Macmillian Press Ltd, 1982.

See also